In-line Inspection Alignment and Matching

In-line Inspection Alignment and Matching

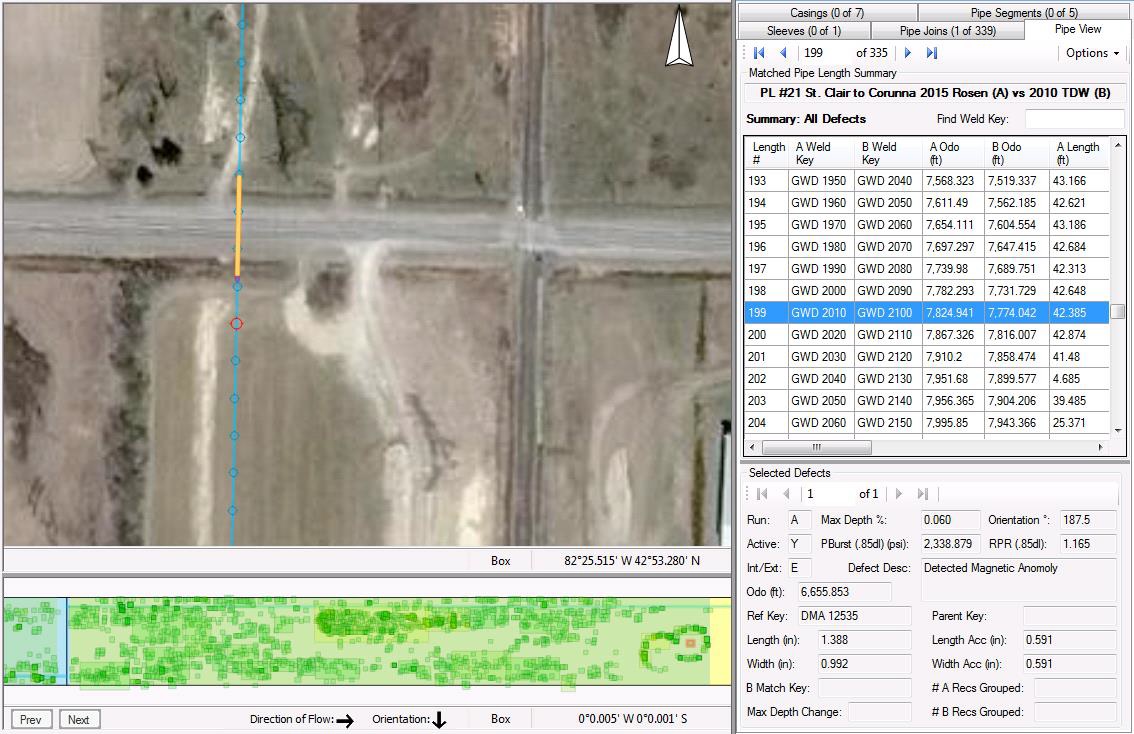

Cylo Technologies offers complete In-line Inspection Alignment and Matching. Every In-line Inspection (ILI), regardless of Tool Vendor, Tool Technology, or Tool Era is modelled in 3D, positioned on the best centerline available for each Pipe Route, and stored in a PODS 5.1-compliant database. Each ILI is matched girth weld to girth weld, defect to defect, millimeter to millimeter and is easily rescheduled as the corporate centerline is altered and improved.

- Alignment and Matching of In-line Inspections across all Tool Vendors

- Alignment and Matching of In-line Inspections across all Tool Technologies such as MFL, USCD, EMAT and Geometry tools

- Full 3D pipeline modelling for unprecedented spatial accuracy

- ILI runs are matched girth weld to girth weld, defect to defect, millimeter to millimeter

- Every ILI data element is modeled in the real world with at least sub-meter accuracy

- Pipeline Asset datasets are generated from the ILI data with the same accuracy

- Fixed cost service with extremely rapid turnaround!

When an In-line Inspection is aligned and matched in its entirety, without data filtering, the ILI is a very effective means of assessing the integrity of a pipeline. Cylo Technologies seamlessly exports these matched ILI and Asset datasets via Excel or SQL for integration into your existing Pipeline Integrity Management processes and corporate GIS systems.

Aligned and matched In-line Inspections and Assets are placed in a 3D Spatial Data Infrastructure and integrated with all other relevant current and historical datasets. This forms the foundation for our revolutionary ILI Data Management system CyloPipeTM, which streamlines your integrity management process and delivers a visual, interactive environment in which to manage your Integrity data.

Key Features

- Alignment and Matching of In-line Inspections across all Tool Vendors and all Tool Technologies

- Easily reschedule every aligned and matched ILI as the corporate centerline is altered and improved

- Non-Proprietary PODS 5.1-compliant Database Interface and Microsoft Excel exports for easy integration with Pipeline Integrity and GIS